By: Randall Ennis, Jan de Jonge and Joe Antonio

At the heart of the African Poultry Multiplication Initiative (APMI) lies a critical element – the supply chain. The APMI program hinges on efficient logistics for dual-purpose poultry (DPP) procurement, vaccine supply, feed ingredients, and distribution channels. A resilient supply chain cultivates trust and assurance throughout the value chain, crucial for both Brooder Units and Small Scale Producers, who are highly sensitive to factors like price fluctuations, input availability, and chick survival rates.

“Security of supply is the success and longevity of any poultry production system,” explains World Poultry Foundation (WPF) CEO Randall Ennis. Every cog in the chain must function harmoniously to ensure continuous production and the consistent availability of birds in the supply chain. Ennis elaborates, “[a]s most of the APMI programs start with small volumes, the production planning is a key to not only efficiency but in the ability to minimize periods of shortage or surplus production.” WPF works closely with our partners, coaching on best practices, offering advice, and connecting them with outside partners as they establish and enhance the supply chain in each of these critical areas.

Why Supply Chain Matters for APMI

Disrupting a single element can have far-reaching consequences. If there’s an issue with the vaccines or their schedule, mortality could skyrocket. Poor transportation can also impact the birds’ survival rates. When dealing with live animals, utmost care is essential. A single mistake can result in significant losses. Any disruption in the supply chain can have a domino effect, impacting the entire value chain and affecting profit for all. Ennis explains, “Gaps in production supply can create delays in placements for the Brooder Units (BUs) and reduce the number of batches that are grown each year. This can reduce the ability of the BUs operators to meet the sales demand and thus reduce revenue from the sale of the brooded birds. In many cases, this is not just a financial issue but an emotional one as the BUs have established a network of farmers who are dependent on them to replenish their flocks and can feel like they have let their neighbors and customers down when they cannot supply.”

DPP Procurement

DPP Procurement

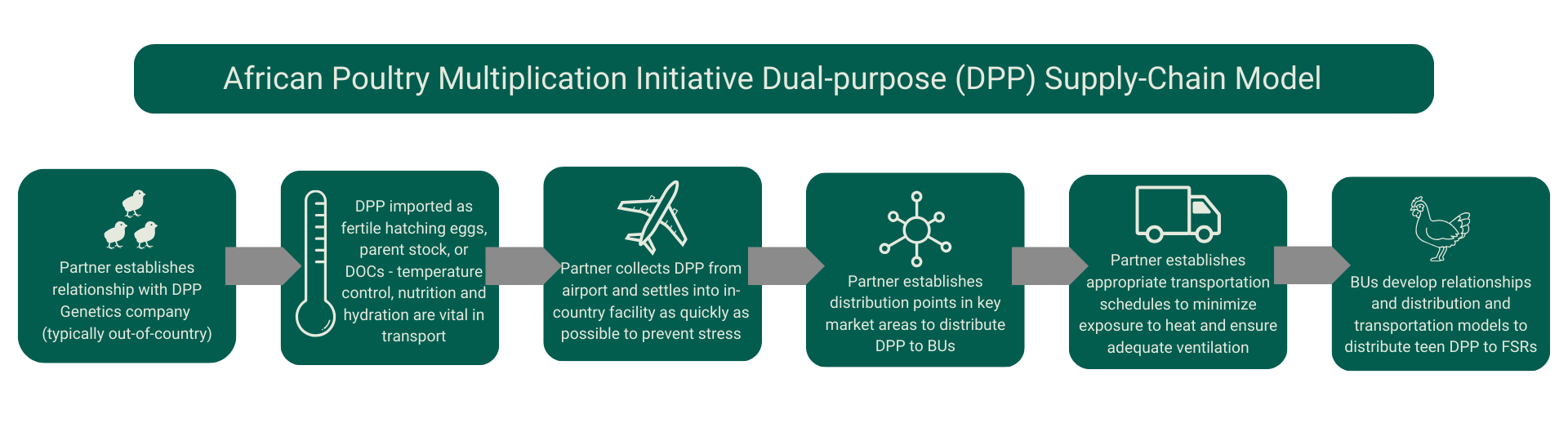

One of the primary supply chain considerations is ensuring a consistent supply of DPP to the private-sector partner and then ultimately to the Brooder Units (BUs) and small-scale producers (SSPs). First, the birds have to arrive in the country, whether it’s day-old chicks, fertile hatching eggs, and the parent stock logistics are complex. In nearly all of our APMI countries, the birds are sourced internationally, which necessitates extensive pre-planning to minimize stress and mortality during transport.

When day-old chicks are imported, like in Sierra Leone and The Gambia, the logistics are even more complex. Jan de Jonge, Senior Program Director for Africa, explains:

“In both these countries, a functioning hatchery was lacking. To kickstart the program and develop value chains, the WPF and private sector partners chose to introduce DPP day-old chicks (DOCs) early, before parent stock and fertile hatching eggs were ready. These DOCs are imported from outside the country, and it’s imperative to maintain precise temperature, hydration and ventilation conditions during their transportation. Ensuring the appropriate import documentation is in order becomes crucial to streamline the process and guarantee the swift collection and delivery of birds, thereby preventing undue delays and potential losses.”

WPF works closely with our partners to develop precise supply projections based on long-term goals and demand forecasts to avoid over or under-supply throughout the program to maintain profit margins. Starting with the end consumer and working backwards, companies must project the demand for the sales of the birds and then calculate the number of BUs needed to supply this demand and then produce enough stock whether from internal production or imports. If at any point this breaks down, then it affects the entire value chain and ultimately the profit margins.

Distribution Channels

Distribution channels must be considered early-on in the project to ensure there is a clear path for healthy birds to get to customers. Each country’s distribution channels are unique, so an initial assessment is crucial. For countries with existing distribution networks, the goal is to enhance and streamline them.

In cases where there aren’t established distribution points, such as in Sierra Leone and The Gambia, we identify where people commonly gather, where they already access other important inputs such as feed and vaccines, and determine what would make suitable distribution locations. We work closely with our partners to select 5-10 initial distribution points, such as markets or transport hubs, and then support them in actively promoting these locations.

Transportation to and from distribution points is paramount, as any lapses can result in chick mortality due to factors like heat and dehydration. We review the road quality and network to determine the appropriate vehicles with adequate ventilation to maintain chick health during transport, and support planning around the best time of day to deliver chicks, typically in the evenings or early morning to limit heat exposure.

Supply and demand comes into play again at this stage. We work closely with our partner to develop effective sales and distribution plans to limit uncollected chicks. This involves factors such as preselling, ensuring accurate egg numbers are set, and optimizing distribution routes. We also promote a phased approach, focusing on one geographical area, building its capacity and demand, and then moving to another. This approach ensures efficient scaling over a longer period and allows successful locations to support the expansion into new regions.

The Vaccine Supply Chain

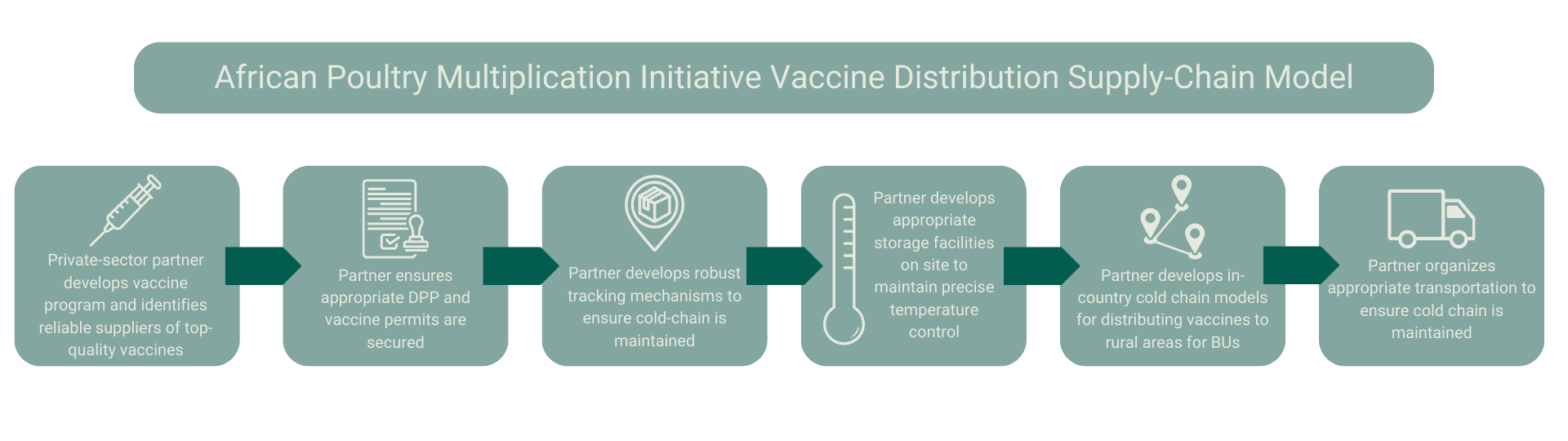

Simultaneously, we must consider the vaccine program for chicks. A proper vaccination program is vital for bird health and survival, thus procuring and handling vaccines correctly is imperative for success. Vaccines demand specialized care to preserve their effectiveness.

APMI Technical Director, Joe Antonio, explains the process:

“It is of utmost importance to choose reliable suppliers and intermediaries to guarantee the delivery of top-quality vaccines. After identifying these vaccine suppliers, it is essential to understand local import regulations and work with the Ministry of Agriculture to obtain any necessary permits for introducing new vaccines into the country. During the transportation of vaccines, robust tracking mechanisms, such as data loggers, are needed for monitoring the cold chain and ensuring that vaccines are delivered in their optimal condition. Upon vaccine arrival, companies must have established storage facilities with precise temperature control to safeguard the vaccines. Further, they must maintain a strong in-country cold chain for distributing vaccines to more rural areas, ensuring high quality vaccines at the BU-level.”

Education plays a significant role at the outset in countries like Sierra Leone and The Gambia. WPF works closely with partners to ensure they understand the significance of high-quality vaccines and the need for a robust cold chain to keep these vaccines viable until administration. We’ve also introduced new vaccine techniques to reduce the need for revaccination, ultimately decreasing mortality rates and improving chick quality for Small Scale Producers.

Feed Ingredients

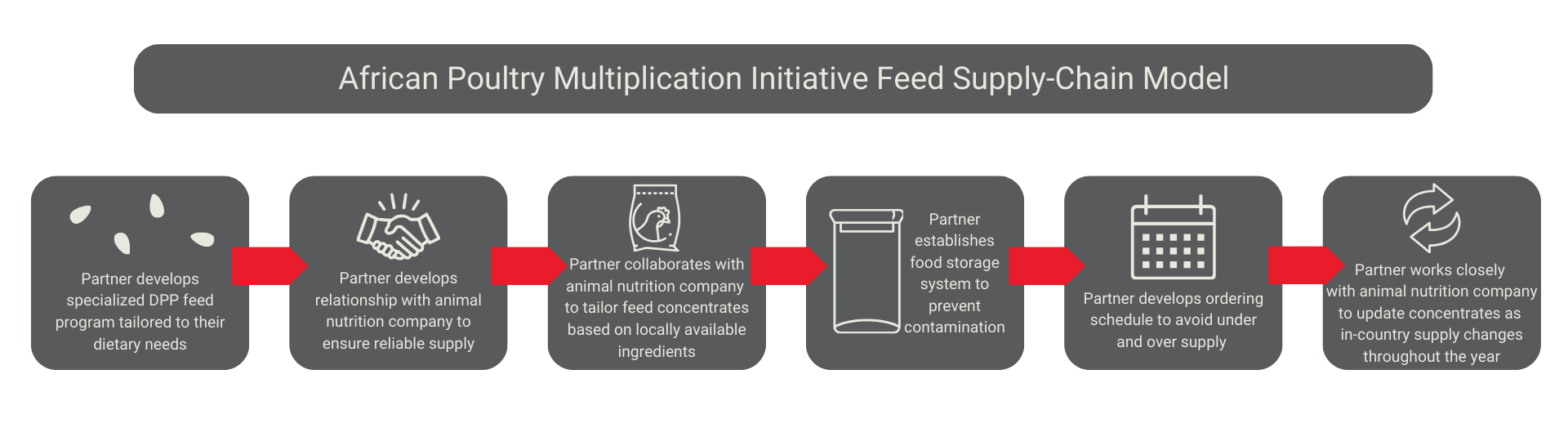

Feed is a critical consideration before introducing birds into a country. DPP, like all birds, performs best with specialized feed formulations tailored to different growth stages. Private sector companies collaborate with animal nutrition firms to create tailored feed formulations that match the birds’ specific dietary needs. Typically, feed is provided in the form of concentrate, which is then blended with locally available ingredients, like maize or limestone from oyster shells. These formulations are adjusted periodically to align with the availability of local raw materials.

In Sierra Leone and The Gambia, our partners established partnerships with feed companies outside of the country. This comes with its own logistical challenges, such as ensuring accurate quantities are ordered and maintaining proper storage systems. Once again, synchronizing supply and demand is vital to prevent expiration or under-supply of feed, which would starve the birds, and to prevent contamination by rodents and pests, which could cause illness in the flock.

Looking to the Future

The APMI program, supported by the World Poultry Foundation, is continuously working with its partners to improve the supply chain. This involves helping to connect local companies to finding more reliable suppliers, mentoring companies on how to reduce gaps or failures in the value chain, and supporting the development of regional hubs to decrease dependence on distant sources, ultimately making poultry development more feasible, affordable, and sustainable in Africa.

A well thought out and robust supply chain ensures the successful development and distribution of high-quality dual-purpose poultry. Through meticulous planning, education, and ongoing management, the program is driving positive change in the poultry industry across Africa.

The APMI Program is being implemented in The Gambia and Sierra Leone with generous funding from the Qatar Fund for Development (QFFD).

CATEGORY

LOCATION